|

The Haynes Brothers

Manufacturers of 'Waspair' products

Waspair History – beginnings 1972

By Terence Haynes

It is a long time ago but recent circumstances ( another broken limb – of which more anon ) has crocked me up so I have time on my hand and as I’m getting to that time of life when I find myself reflecting on things I’ve done, things I regret and some things I’m proud of. Of which Waspair covers all three.So back to 1972. My two brothers ( elder half-brother John and younger Robin ) and I had grown up almost next door to the famous Biggin Hill airfield and so much of our childhood memories include aircraft - I was model aircraft crazy into my teens, until I discovered motorcycle racing that is, which is another story. Anyhow In my mid twenties I worked in a large engineering company & had made my way up via old-fashioned apprenticeship to be in charge of a big automation project, so had good access to machine tools, some practical skills and could come and go without ‘clocking in’. Rob worked nearby in the family clothing factory, managing the business, driving the delivery van and looking after a huge array of industrial sewing machines, but in his spare time he did quite a bit of private flying in Cessna’s at Biggin on his way to get a PPL. John seemed more interested in his own growing business empire, but by 1972 had made enough to look for fresh challenges and suddenly announced he was going to build a light airplane. Now John is a very very clever guy but he doesn’t go by the rules. He hadn’t bought plans and this was to be all his own ideas, but his sketches looked to me disconcertingly like deck chairs loosely attached to barn doors. Frankly I worried that he had the energy & drive to overlook that what he might build wasn’t structurally or aerodynamically safe or that he would need permissions and airworthiness checks etc - all the kind of bureaucratic stuff that bored him.

By coincidence I’d come across some American magazines that had pictures of the latest California craze – ‘Sky surfing’ on delta kites skimming a few feet over sun-kissed sand dunes with adoring bikini-clad girls looking on. It seemed wildly attractive, but more to the point much safer than deck chairs & barn doors, and clearly it could be done. More interesting to John was that it seemed there was no inspection or permissions needed – ideal! So magazine photo’s were scaled up and models built and eventually John opened his wallet to buy the materials to build the real thing. We had no plans or instructions and even though I’d got a reasonable grip on the importance of things like lift & drag and pitching moments and knew something of the flex wing Rogallo ‘Fleep’ there was no information that I could find at the time ( remember this is pre-Internet and Google search ) on where the CG should be or even what size would be right to carry South London lads.

In the event practical considerations of what length alloy tube could be bought locally dictated the size rather than theory, and the rest was guesswork. It ended up really small with just over 16’ spars and I drew it up on a 90deg sail planform with 80 deg airframe nose angle giving a nominal 5deg of billow, but this was adjustable, which with the benefit of hindsight was a good thing. Anyhow, we had a real advantage in that the family clothes-making business had dozens of sewing machines & overlockers, large cutting tables and a big area where a hang-glider could be assembled. So off we went. I made the airframe components after work in the evening, while Rob made the sail up from very flimsy pale blue ‘ripstop’ nylon and John went hunting for all the bits and pieces. At my insistence the sail was glued onto the 1 ¾” leading edge tubes with impact adhesive because I had the horrors about what might happen if the stitching failed. This also gave a theoretical advantage in that we could adjust the amount of billow or slackness in the sail by rotating the leading edges to, as it were, furl in the sail. It was obvious to me that the curvature of the canopy was important aerodynamically , and I devised a sort of vernier coupling at the nose and a clamp at the cross-boom joints rather than through-bolts to allow the leading edges to be rotated at small intervals. In the event I think we ended up with something nearer to 4deg of billow but meticulously checked so this was equal each side. This was certainly tighter than planned or what we now know most of our contemporaries were using, which in hindsight is interesting.

The rigging was plastic-covered marine cable secured with clamps, and the control frame was made from 1 ¼ “ alloy tube from a WD surplus warehouse in Streatham. The same Alladin’s cave provided a parachute harness which we adapted and clipped via caribiner clips to two loops that went around the cross-boom.

Just before my birthday in late August ’72 we loaded the finished ‘No. 1’ ( although it didn’t have a name at this time ) into Rob’s gown van and headed for the highest point we knew of locally – Box Hill in Surrey. On reflection it was an absolutely perfect autumn day with a steady, brisk wind directly up the slope, and a sufficiently clear area in front of us to land without power lines or roads or trees. Or so we thought.I can remember this like it was yesterday. John went first but didn’t get off the ground. We adjusted some of the cables because it all seemed very wobbly ( there was no Kingpost ) and Rob was next. Looking back I don’t think any of us really could take in that after a determined run he launched successfully and was actually flying, did some gentle turns and then landed safely. I think he was in the air for less than 30 seconds, but it worked! The thing actually flew – which frankly suddenly scared me witless, not least because I was still limping from a nasty motorcycle crash that had almost cost my left leg. Up to now I suppose I ’d thought of this as much like a big model aircraft and a sort of practical engineering exercise that would stop my brother killing himself – but this thing actually flew. And it was my turn next….

I clipped in and with my heart banging I stumbled half-heartedly down the hill, then ignominiously tripped, which damaged the rigging so that it was all lop-sided. Whilst the glider was repaired ( it was turned over on its back, which is why the pictures show a large dirt stain ) my wife helped me fashion an impromptu splint for my gammy leg from a length of heavy-duty cardboard tube ( which the sail-cloth had come on ) strapped up with gaffer tape. Meanwhile John put the harness on for his second go. By now the breeze had picked up and john launched after another determined run, not losing height and in fact drifting back slightly so that he hovered above us briefly as we ran below, all of us whooping madly, then landed safely at the bottom of the hill just before the tree line. We were ecstatic and it was my turn again. By this time we had gathered a small knot of onlookers, so no time for 2nd or 3rd thoughts. One, two three steps, swearing to myself under my breath …. “ faster, faster, damn it, faster – don’t trip.. “, then suddenly I was flying… The ground fell away beneath me and all too soon I realised I was heading over the tree line at the bottom of the hill. I started to turn away left running parallel with the trees towards the next clear field, then abruptly I started going up alarmingly as I caught lift over the trees. Despite pulling back on the control frame as hard as I could the thing tip-stalled and I spiralled into the ground with an almighty thump, breaking the control frame and ending the day’s activities. But I was alive, I’d wrenched my leg but it was still in one piece – and I had flown – in fact I’d gone up higher than the take-off point and soared for well over a minute. And as we celebrated at a local pub that evening we knew that something had started…

© Copyright Terence Haynes 2013 All Rights Reserved

|

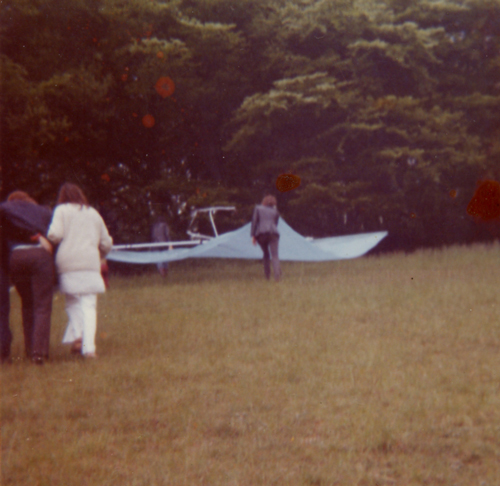

Robin Haynes taking his very first flight in the 'A' styled hang glider at Box Hill August 1972

|

Robin Haynes setting up the 'A' styled hang glider at Box Hill August 1972

|

Terry Haynes limping back up Box Hill after his very first flight

Amazingly he was lifted up by a thermal above the tree line and then dumped hurting his leg

August 1972

|

Robin Haynes taking off with the 'Waspair' Super Nova at Steyning Bowl

All the material on this site is subject to copyright Much of this material may only be reproduced with the written permission of the copyright holder |